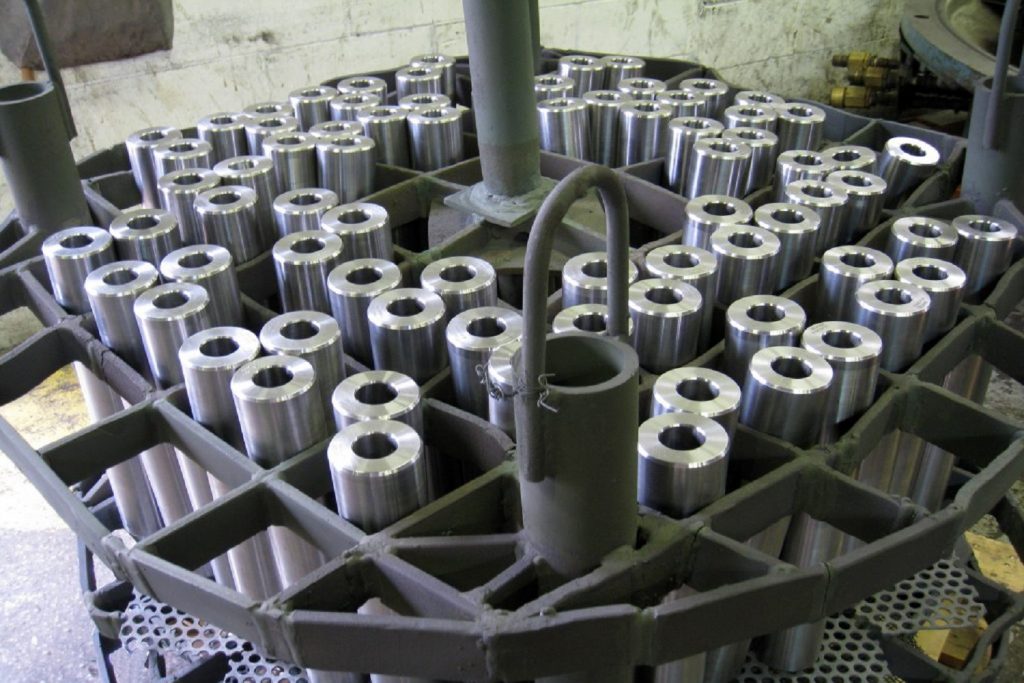

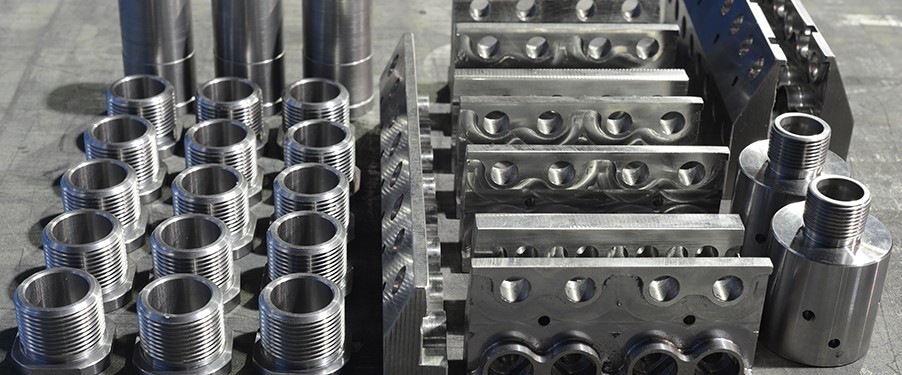

We uses state of the art equipment for our vacuum heat treatment services. Our vacuum furnace, along with our treatment expertise, allows us to provide our services to a wide range of customers.

With heating capabilities up to 1300°C and quenching methods using nitrogen, argon, hydrogen, or water, we are able to treat carbon alloys, stainless, and tool steels, as well as titanium and high nickel alloys. Our customers turn to us for vacuum heat treatment services because of the many benefits it provides. Vacuum heat treating allows materials to maintain dimensional properties and surface cleanliness, while adjusting material strength and hardness. It provides an ultra-clean process atmosphere resulting in minimal surface contamination, while improving surface properties and wear resistance. We offer flexible project volumes and quick completion times. We are sure you will be pleased with the vacuum heat treatment services we provide. Please contact us today to see how we can help you meet your goals.

| Applications | Medical Surgical Aerospace Bearings Tool & Die Military/Defense High Value Machined Parts Springs Brazed Components |

| Benefits | Maintain dimensional properties and surface cleanliness Adjust material strength and hardness Ultra clean process atmosphere Minimal surface contamination Improve surface properties Improve wear resistance Stronger alloys Relieve stresses |

Reduced costs

Vacuum heat treatment is surprisingly economical compared with tradition methods. In most cases it will actually be cheaper whilst offer far superior quality!

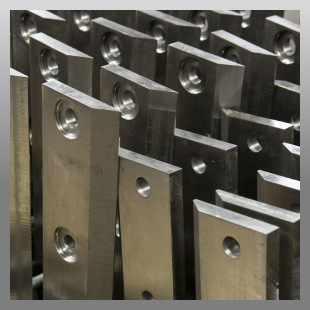

Reduced distortion

Distortion is significantly reduced due to the precise control of the temperature within the furnace, and the heating and cooling speeds. This means a reduction in the amount of grinding or machining required post treatment.

Increased component life

With vacuum heat treatment there is no opportunity for corrosion to set in, unlike other treatment methods which can leave corrosive residues.

Less waste

Reduced distortion following treatment means a greater proportion of treated product will be suitable for use or for further processes.

Cleanliness

Working within a vacuum, surface oxidization is vastly reduced, and no contaminants are used (such as with caustic salt baths), meaning that no residuals remain in places such as blind holes. Items will often appear as bright after treatment as before, obviating the need for further machining or grinding post treatment.

Environmental and safety issues

Vacuum heat treatment is environmentally friendly as no poisonous salts are used in the process. This is also a safety benefit to our own staff during treatment, and your staff during subsequent handling or machining.